Coating Solutions

Description

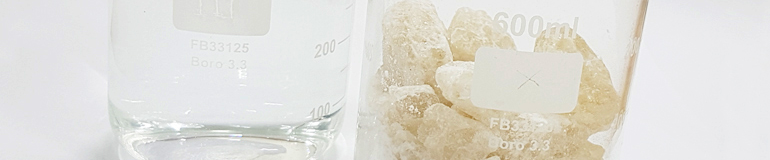

Flutec LE12 and LE15 are solutions of a low molecular weight perfluorocarbon oligomer in a low boiling-point, volatile perfluorocarbon liquid.

Flutec LE12 and LE15 are clear, have very low surface energies and high contact-angles with water.

They are highly chemically-resistant to most liquids and solutions not containing fluorine atoms and will repel a variety of oils, lubricants and aqueous solutions of high and low pH.

Coatings remain flexible at low temperatures and melt between 60°C. and 80°C.

Uses

Items and surfaces coated or impregnated with Flutec LE12 and Flutec LE15 are simultaneously hydrophobic and oleophobic. This means that the solutions can be used for:

- Protecting fully-assembled printed circuit boards and other electronics assemblies against condensed, atmospheric moisture.

Areas: External assemblies, intruder alarms, traffic systems, sea-going electronics, agricultural electronics. - Impregnating / coating woven and non-woven fibres for protection against water and chemicals.

Areas: Paper for pet-food container, book protection, coating filter media. - Coating applicator jets and nozzles to prevent clogging and to control shapes of droplets.

Areas: Ink-jet printers, adhesive applicators. - Preventing migration of a large range of oils, lubricants, fluxes and inks into areas where they are not required.

Areas: Bearing-races, various containers (to ensure complete drainage), adhesive-joining “overspill”. - Releasing resin mouldings from their moulds.

Areas: Cold-cast1 resins, RTV-silicones.

Application Methods

Depending upon the specific use, Flutec LE12 and Flutec LE15 coatings can be applied by:

- Dipping

- Spraying

- Brushing

- Flood-Coating

- Curtain-Coating

- K-bar Coating

- Hypodermic or other nozzle spotting

Dipping, where practical, is preferred as equipment is available commercially which handles parts automatically and effectively recovers the solvent during drying of the coating.

Post-baking of dried films is not necessary.

Application equipment can be cleaned with any of the range of Flutec perfluorocarbon liquids.

Typical Physical Properties

| Form | Mobile liquid |

| Solids content | 2% w/w (LE12), 5% w/w (LE15) |

| Appearance | Colourless liquid |

| Specific Gravity | 1.7 |

| Flash point | None |

| Surface Energy of dry film | 18-19 dynes cm-1 |

| Contact angle (DI water) | 110° |

Handling and Storage

Flutec LE12 and LE15 should be stored in a cool area and preferably in their tightly-closed original containers. There are no hazards involved in handling either material. Refer to the Safety Data Sheet for more details.

Packaging

Flutec LE12 and Flutec LE15 are available in 5 kg containers. Larger containers are available on request.